105

105

THE IMPORTANCE OF DELTA T

Key Points: The Importance of Delta T in a Boiler System

1. Delta T and System Performance:

-

The system’s performance depends on effective heat transfer (BTUs) to the space.

-

Poor performance occurs if BTUs leave the boiler but return unused.

2. Delta T Design Standards:

-

Traditional design aims for a 20°F Delta T to protect cast iron boilers from thermal shock (risk if return temps fall below 140°F).

-

Typical system design uses:

-

200°F supply → 30°F Delta T → 170°F return

-

180°F supply → 20°F Delta T → 160°F return

-

3. Balancing System Flow:

-

Properly selected emitters and pipe sizes ensure correct GPM flow and pressure drop.

-

Oversized pumps can cause BTUs to return to the boiler instead of being delivered to the building.

4. Managing Boiler Efficiency:

-

Condensing boilers should lower return temps below the dew point to maximize efficiency.

-

Using variable frequency drives (VFDs) or Electronically Commutated Motor (ECM) pumps optimizes flow control.

5. Primary/Secondary Loop Piping Benefits:

-

Improves both thermal and electrical efficiency.

-

Reduces hardware costs by minimizing or eliminating the need for three-way valves.

-

Results in less wear on piping components and better temperature control for enhanced comfort.

Performance of a hydronic system is completely dependent on the change in temperature through the system. If the emitters are not delivering BTUs to the space performance is bad. If the BTUs leaving the boiler are returning unused the performance is bad. In the past systems were designed for a twenty-degree delta T for a very good reason. Cast iron boilers are vulnerable to thermal shock if the return temperature falls below 140 degrees.

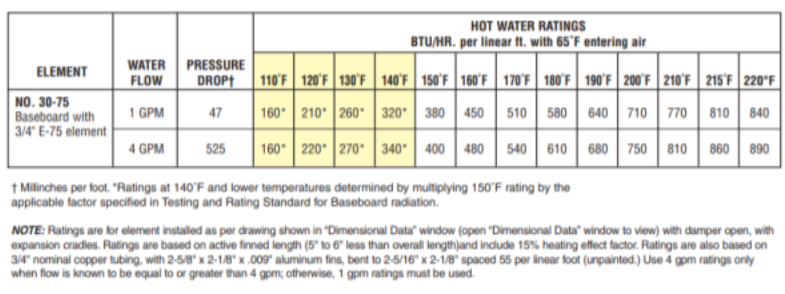

Capacity tables for most manufacturers of finned tube radiation are based on 200 degree entering water temperature. Why 200 degrees? It is below the temperature where it would flash into steam by a safe margin. If the supply was 200 degrees and the design temperature drop was thirty degree the return would be 170 degrees. No danger of thermal shock to the boiler would occur.

If 140 degrees is the lowest return we want to allow, a thirty degree drop would mean we want 170 degrees minimum supply. These are the extremes. In reality, typical systems design is 180-degree supply temperature with a twenty-degree drop.

Systems that are designed to deliver the requires BTUs to maintain design conditions, 70 degrees indoors at zero degrees outdoors, give us the starting point. Selecting emitters that deliver the BTUs for design conditions dictates the required GPM of flow. Pipes sized to carry the required flow and the cumulative pressure drop through the system gives us the GPM and friction loss or head. Now we make a pump selection that satisfies those requirements. The result will be that the BTUs are delivered to the building rather than returning to the boiler due to an oversized pump.

If we look further at the capacity tables for most emitters, we will find ratings at other entering water temperatures. We can plot the curve of a typical boiler reset control with a 1:1 ratio to tell us what the water temperature is at any given outdoor temperature. Likewise, we can plot a line from no heat loss at 70 degrees to our full load at zero. We will then know the BTUs required at any given outdoor temperature. The capacity tables will tell us how much radiation is required to satisfy the load at different entering water temperatures.

There is near zero concern about thermal shock in a condensing boiler so we now lower the supply temperature far enough to bring back return water below the dew point temperature. Only then does the condensing boiler pay for itself.

Because loads vary, the required flow varies too. Pumps controlled by variable frequency drives or Electronically Commutated Motors deliver load matched GPM. True Electronically Commutated Motor pumps give the most accurate control of flow. If we have flow through the system operating at optimum levels, we can then focus on the boiler room. The piping design of a building matters in performance. The preferred method is primary/secondary loop piping. We gain electrical efficiency and thermal efficiency in the boiler by taking this systems approach.

Usually hardware costs are reduced in this approach as well. The need for three-way valves is reduced or completely eliminated. Motors of less horsepower do the job using less energy. Wear on piping

component and control valves goes away. Creature comfort is enhanced. A change in space temperature is the reason for a heating system in the first place.

Dallas Strong

Johnstone Supply Technical Sales