88

88

Pulling a vacuum or "dehydrating" a system is an extremely important practice, and a must if you want the Air conditioning system you are installing/servicing to last. With the use of POE and PVE oils becoming more the norm, getting the vacuum done right is more imperative than ever before. These oils are not just lubricants but the are hygroscopic and detergent like. This means they clean, and love moisture. A properly done vacuum, will tell us with confidence that we have a sealed system that is clean, dry and tight.

Minimize your connections, DO NOT use your charging manifold for pulling a vacuum. And ALWAYS use a core removal tool to remove the valve core, and isolate the system during the "Decay" test.

Use a Micron gauge for best and accurate results. Attach to the side of the Core tool. Some tools will have a tag to show you which port is for the gauge, and which is for the pump.

For Most residential systems 5ton and under with up to 50' of lineset:

1. Attach the pump to the suction line service valve (core tool attached and core removed)

2. Pull a vacuum to 250 microns or less (should take less than 30min and as little as 10)

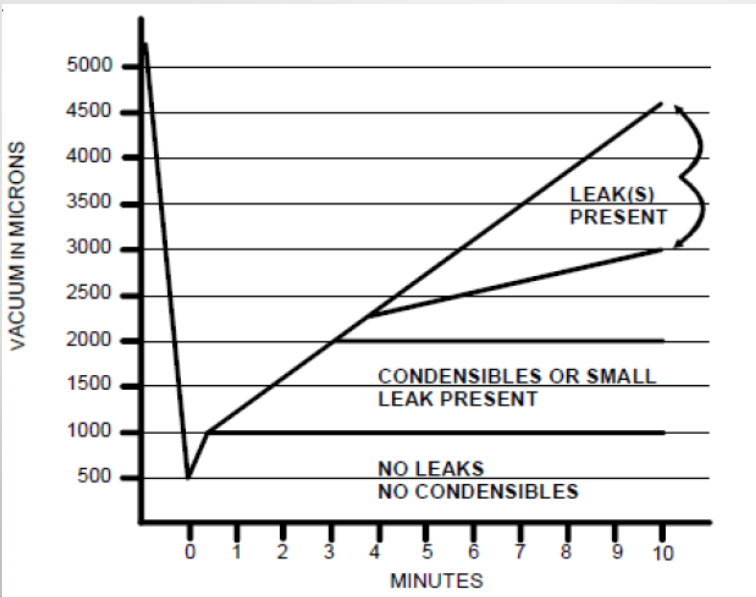

3. Valve off the core tool, stop pump, and monitor for a minimum of 10 minutes

-If the pressure rises to 1000 microns or less and remains steady for 10 minutes, the system is considered leak free and you can proceed to start-up.

-If the pressure rises above 1000 microns but holds steady below 2000 microns for ten minutes, moisture and/or non-condensables may be present or the system may have a small leak.

-If pressure rises above 2000 microns after 10 minutes, a leak is present and must be investigated before start-up can begin.

If you encounter a system that cannot seem to hold a vacuum, it may be necessary to pressurize the system and check for leaks with soap bubbles. Start your leak checks at the most obvious places first like braze or solder connections. Check for possible leaks at your hoses or tools, the o-rings could be shot or have failed. Another place to check for leaks would be the factory installed service valves themselves, they may have gotten too hot during brazing. The next place to investigate for leaks, would be the condenser and evaporator coils themselves. The line-set would be the last, and most unlikely spot for a leak, but still worth inspecting.

Carlos Sanchez

JSWMI

HVAC North